As society continues to grapple with the pressing challenges of waste management and resource depletion, innovative solutions are emerging to transform how we recycle and reuse materials. One of the most promising advancements in this realm is cold sinking, a revolutionary technique for recycling ceramics and plastics.

The increasing volume of waste generated globally is staggering. According to the World Bank, the world produced approximately 2.01 billion tons of municipal solid waste in 2016, and this figure is expected to reach 3.4 billion tons by 2050. A significant proportion of this waste consists of plastics and ceramics, both of which pose unique challenges for recycling.

Plastics are ubiquitous in modern society, found in everything from packaging to automotive parts. However, their durability, which makes them useful, also complicates their disposal. Recycling rates for plastics remain low, with only around 9% of plastic waste being recycled globally. The rest ends up in landfills, incinerators, or the natural environment, contributing to pollution and environmental degradation.

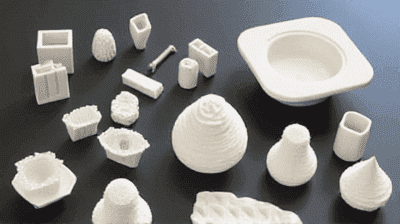

Ceramics, commonly used in pottery, tiles, and sanitaryware, also face recycling hurdles. Unlike metals and plastics, ceramics are notoriously difficult to recycle due to their hardness and brittleness. While some methods exist for grinding ceramics into aggregate for construction, the overall recycling rate remains low. The need for innovative technologies to address these challenges is imperative to foster a circular economy.

The recycling process for materials can be energy-intensive. Traditional methods often require high temperatures and significant energy inputs to break down materials. Therefore, developing energy-efficient recycling techniques is vital for minimizing carbon footprints and promoting sustainable practices.

Cold sinking is an emerging recycling technique that utilizes a low-energy process to separate and recycle ceramics and plastics. This method involves the immersion of materials in a liquid medium at relatively low temperatures, allowing for the efficient separation of components without the high energy costs associated with traditional recycling methods. The term "cold sinking" refers to the concept of using a cold liquid (often water or a solution) to facilitate the segregation of materials.

Cold sinking operates on the principles of density and buoyancy. Different materials have varying densities, which can be exploited in a liquid medium. When a mixture of ceramics and plastics is submerged in a liquid, the materials separate based on their density differences.

Density Differences: Plastics generally have a lower density than ceramics. This difference allows plastics to float while ceramics sink when immersed in an appropriate liquid.

Liquid Medium: The choice of liquid medium is crucial for effective separation. Water is often used, but other solutions can enhance the effectiveness of the process, depending on the specific materials being recycled.

Separation Process: After immersion, the plastics can be easily skimmed off from the surface, while the ceramics remain at the bottom. This simple yet effective mechanism allows for the rapid and energy-efficient separation of the two materials.

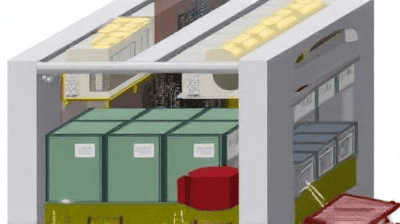

One of the primary applications of cold sinking is within recycling facilities. Traditional recycling processes for ceramics and plastics can be labor-intensive and costly. By implementing cold sinking technology, facilities can streamline operations, reduce energy consumption, and enhance overall efficiency.

Municipal waste management programs can benefit from cold sinking as a means to efficiently separate recyclables from general waste. This technique allows for the recovery of valuable plastics and ceramics that would otherwise be lost in landfills.

In construction and demolition settings, waste materials often include ceramics (from tiles and sanitary products) and plastics (from packaging and fixtures). Cold sinking can be employed to recover these materials for recycling or reuse, reducing the environmental impact of demolition activities.

Cold sinking also holds promise in educational and research settings, where students and researchers can explore the principles of material science and recycling. This hands-on approach to learning can promote awareness of waste management issues and innovative solutions.

One of the most significant advantages of cold sinking is its energy efficiency. Unlike traditional recycling methods, which often require high temperatures and extensive energy inputs, cold sinking operates at ambient temperatures. This efficiency can lead to substantial cost savings and reduced carbon emissions.

By minimizing energy requirements and streamlining the recycling process, cold sinking can reduce operational costs for recycling facilities. Lower processing costs can lead to increased profitability and enhanced sustainability for operations.

Cold sinking has the potential to improve recovery rates for ceramics and plastics. By effectively separating these materials, more resources can be diverted from landfills, leading to a more circular economy.

The simplicity of the cold sinking process makes it easier to implement in existing recycling facilities. Fewer complex steps involve less machinery and labor, which can enhance efficiency and productivity.

Cold sinking contributes to resource conservation by capturing valuable plastics and ceramics that can be reprocessed into new products. This effort helps reduce the demand for virgin materials, promoting sustainability and reducing environmental impacts.

By increasing recycling rates and diverting materials from landfills, cold sinking can help mitigate the environmental impact of waste disposal. This strategy aligns with global efforts to minimize waste and promote circular economy principles.

While cold sinking is effective for separating specific types of ceramics and plastics, material compatibility is crucial. Variations in plastic densities or ceramic compositions may affect the efficiency of the process. Ongoing research will be essential to optimize the technique for various material types.

Implementing cold sinking technology may require upfront investments for recycling facilities, including equipment and liquid medium setup. However, the long-term cost savings can mitigate these initial expenditures.

Increasing awareness of cold sinking and its benefits is vital for widespread adoption. Educational campaigns and outreach efforts will be essential in informing communities and industries about the advantages of this innovative recycling method.

Supportive regulations and policies can encourage the adoption of cold sinking within recycling programs. Collaboration among government agencies, recycling facilities, and industry stakeholders will be essential in creating a conducive environment for this technology.

While cold sinking shows promise, ongoing research and development will be necessary to refine the process and expand its capabilities. Innovation in materials science and engineering techniques can enhance the effectiveness of cold sinking.

Research into alternative liquid mediums for cold sinking could further enhance efficiency and effectiveness. By exploring various solutions, researchers can identify those that improve separation performance or reduce environmental impact.

Cold sinking can potentially be integrated with other recycling methods, creating hybrid systems that optimize resource recovery. Combining technologies may lead to improved recycling rates and reduced costs for facilities.

As awareness of cold sinking grows, opportunities may arise to expand this technology into new markets. Adaptable systems could be developed for diverse industries that generate recyclable ceramics and plastics.

Governments worldwide are increasingly emphasizing sustainability and waste reduction. Supporting policies and regulations that promote cold sinking could facilitate its adoption across various sectors.

Engaging communities in the recycling process can foster a sense of ownership and responsibility for reducing waste. Educational initiatives that highlight cold sinking's benefits can encourage greater participation in recycling programs.

The shift toward circular economy models is gaining traction globally as businesses and governments alike recognize the importance of resource conservation and waste reduction. Cold sinking aligns with these trends by facilitating the efficient recycling of valuable materials.

Rapid advancements in recycling technologies are transforming the industry. Innovations designed to enhance efficiency and effectiveness are becoming increasingly prevalent. Cold sinking represents one such significant innovation in the pursuit of sustainable recycling practices.

Collaborative efforts between governments, businesses, and non-profit organizations play a vital role in advancing recycling initiatives. By forming partnerships and sharing knowledge, stakeholders can create more effective recycling systems and promote the adoption of new technologies like cold sinking.

As consumers become more aware of sustainability issues, there is a growing demand for transparency and accountability in recycling practices. Businesses that adopt innovative methods such as cold sinking can stand out as leaders in responsible waste management.

Educational programs that promote recycling awareness and the importance of sustainable practices are essential for building a more informed public. Advocacy efforts can spur demand for innovative recycling technologies and create momentum for systemic change.

Cold sinking presents an innovative and energy-efficient solution for recycling ceramics and plastics, two materials that have historically posed significant challenges to waste management. By harnessing the principles of density separation, cold sinking allows for the effective recovery of valuable materials while minimizing energy consumption and operational costs.

The numerous benefits of cold sinking, including improved recovery rates, resource conservation, and simplified processes, position it as a viable strategy for achieving a more sustainable future. However, addressing challenges related to material compatibility, public awareness, and regulatory support will be critical for successful implementation.

As we continue to seek innovative solutions to environmental challenges, cold sinking embodies the potential for transforming waste materials into valuable resources. By promoting a circular economy and embracing new technologies, we can work toward reducing waste, conserving resources, and promoting sustainability for generations to come.